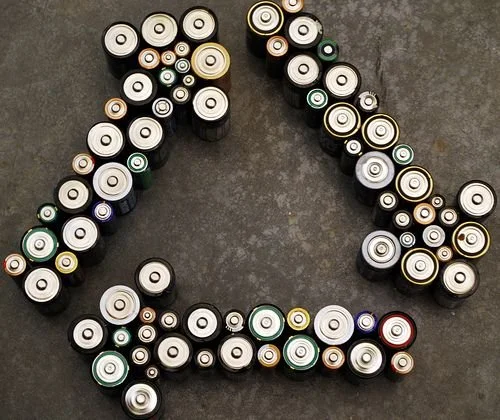

POWERING CIRCULARITY

OPTIMIZING MATERIAL LIFECYCLES

POWERING CIRCULARITY OPTIMIZING MATERIAL LIFECYCLES

E-WASTE & BATTERY RESOURCE RECOVERY

While many view electronic waste as a liability, Cationics approaches it as a high-value repository of critical minerals. Our facility serves as a technical hub for the systematic recovery of lithium-ion batteries and complex electronic architectures. We don’t just recycle; we refine, reclaiming the building blocks of modern technology to support a truly circular industrial economy.

HOW IT WORKS

Advanced Fractional Segregation

-

We move beyond basic crushing. Our technicians perform precise manual separation to isolate PCBs, high-impact polymers, and ferrous/non-ferrous alloys.

-

We utilize a specialized identification process to categorize battery cells by chemistry (NMC, LFP, Cobalt-heavy), optimizing them for high-yield mineral extraction.

-

Our facility features dedicated containment zones for the isolation and treatment of toxic materials, ensuring zero-leakage into the biosphere.

-

We produce high-quality material streams including Lithium, Cobalt, Nickel, and Copper prepared to the technical specifications required for secondary manufacturing.

WHAT SETS US APART

-

Superior Recovery Yields

Our multi-stage segregation protocols minimize material loss, outperforming traditional shredding-only facilities.

-

End-to-End Traceability

We provide comprehensive documentation for ESG reporting, giving our partners a transparent audit trail from collection to final recovery.

-

Localized Expertise

Strategically located in Nagpur, we offer logistical efficiencies and lower carbon footprints for businesses across Central India.

-

Safety-First Infrastructure

Our facility is designed specifically for battery management, featuring advanced thermal monitoring and fire suppression systems far beyond standard e-waste requirements.