POWERING CIRCULARITY

ADVANCED MATERIAL REFINING

POWERING CIRCULARITY ADVANCED MATERIAL REFINING

ADVANCED MINERAL RECOVERY

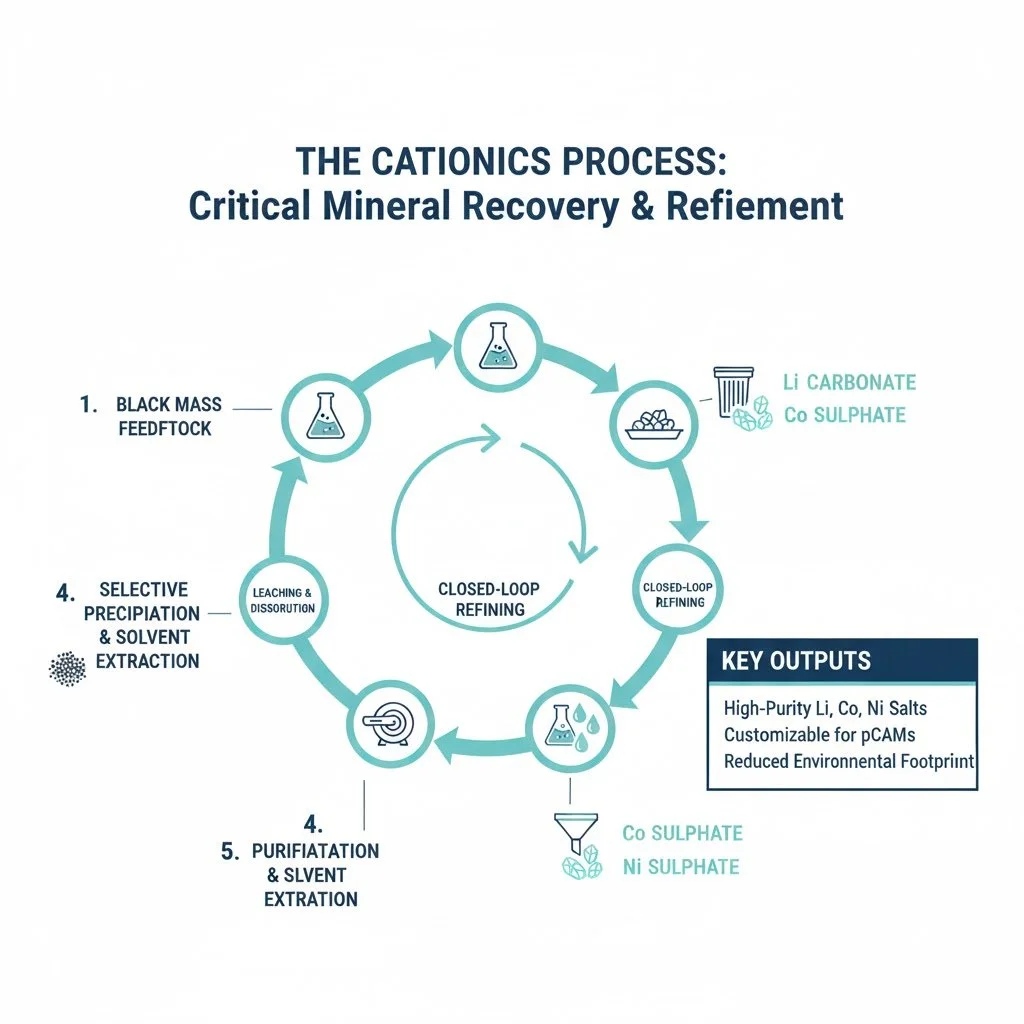

As the global demand for energy storage scales, Cationics Pvt. Ltd. provides the technical infrastructure required to sustain a circular battery economy. We specialize in the high-fidelity recovery of critical minerals from end-of-life (EoL) mobile battery architectures. By diverting hazardous waste from landfills and converting it into high-purity feedstock, we mitigate the environmental risks of virgin mining and secure the domestic supply chain for essential battery-grade materials.

HOW IT WORKS

Technical Recovery Protocol

-

We utilize authorized, traceable channels to aggregate end-of-life mobile batteries. Our intake protocol includes sophisticated sorting based on cell chemistry and state-of-health (SoH), ensuring each material stream is optimized for its specific recovery pathway.

-

Safety is our operational baseline. Batteries are de-energized and dismantled within climate-controlled environments to neutralize thermal runaway risks. This stage ensures that hazardous electrolytes are contained and processed without environmental exposure.

-

Utilizing a hybrid of mechanical separation and state-of-the-art hydrometallurgical processes, we isolate the "Black Mass" and extract high-value elements. This technical focus allows us to reclaim Lithium, Cobalt, Nickel, and Manganese with minimal loss.

-

The Cationics process concludes with the refinement of recovered minerals to stringent technical standards. These materials are reintegrated into the manufacturing ecosystem as secondary raw materials, effectively closing the loop and reducing the ecological footprint of new battery production.

Cationics operates with total transparency, providing our partners with comprehensive documentation and data to support EPR (Extended Producer Responsibility) mandates and ESG reporting requirements.

WHAT SETS US APART

-

Superior Recovery Yields

Our multi-stage segregation protocols minimize material loss, outperforming traditional shredding-only facilities.

-

End-to-End Traceability

We provide comprehensive documentation for ESG reporting, giving our partners a transparent audit trail from collection to final recovery.

-

Localized Expertise

Strategically located in Nagpur, we offer logistical efficiencies and lower carbon footprints for businesses across Central India.

-

Safety-First Infrastructure

Our facility is designed specifically for battery management, featuring advanced thermal monitoring and fire suppression systems far beyond standard e-waste requirements.